Non-Stop Express Service

Ottawa’s Largest Wire Saw Job Speeds Underground Rail Expansion

The construction of Ottawa’s state-of-the-art light rail transit system (OLRT), named the Confederation Line, is the Canadian city’s largest transportation infrastructure project in history with a price tag of $2.1 billion CAD ($1.6 billion USD). This past summer, as the project reached the development of a 2.5-kilometer (1.6-mile) stretch of underground rail line under downtown Ottawa, a professional concrete sawing and drilling contractor was needed to create a large opening at one of three newly-constructed underground stations.

The contractor made a roof opening approximately 44 by 8 meters (144 by 26 feet).

Building a traffic-separated downtown tunnel was the largest single undertaking of the Confederation Line and the key to solving the transit bottleneck in downtown Ottawa. The downtown tunnel has three stations—Lyon, Parliament and Rideau. Advanced mining techniques were used during construction of the tunnel to minimize noise and vibration for residents and businesses, so general contractors Rideau Transit Group (RTG) and Ottawa Light Rail Transit Constructors (OLRT-c)—both consortiums of Canadian and international companies—wanted to continue to adopt this policy when roof openings were required in the recently-poured station tunnel walls.

CSDA member Capital Cutting & Coring Ltd. of Ottawa was selected to make a roof opening approximately 44 by 8 meters (144 by 26 feet) at the new Parliament OLRT underground station using concrete wire sawing techniques with diamond tools. The opening would be used for various shafts and access points to connect the station with street level, and would be made by creating 26 cut concrete pieces each weighing between 25 and 30 tons (50,000 and 60,000 pounds).

Dave Thompson, vice-president of Capital Cutting & Coring Ltd., explained, “This was our biggest wire sawing job ever and the largest one of its kind in Ottawa that I know of. The construction of the Confederation Line had already been underway for four years before we arrived on the jobsite. The wire saw was chosen for its ability to cut manageable sections from huge concrete structures with speed, efficiency and low noise and vibration.”

To keep the overall project on schedule, the cutting contractor was given just three weeks to complete all wire sawing tasks at the Parliament Station West Entrance and remove the cut sections from the jobsite. This was one of five cutting locations required overall. Capital Cutting & Coring calculated that the company would need to run three of its Hydrostress SB wire saws continuously in order to meet the time frame set by the general contractor.

Wire saw operators performed 144 linear meters (472.4 feet) of cutting.

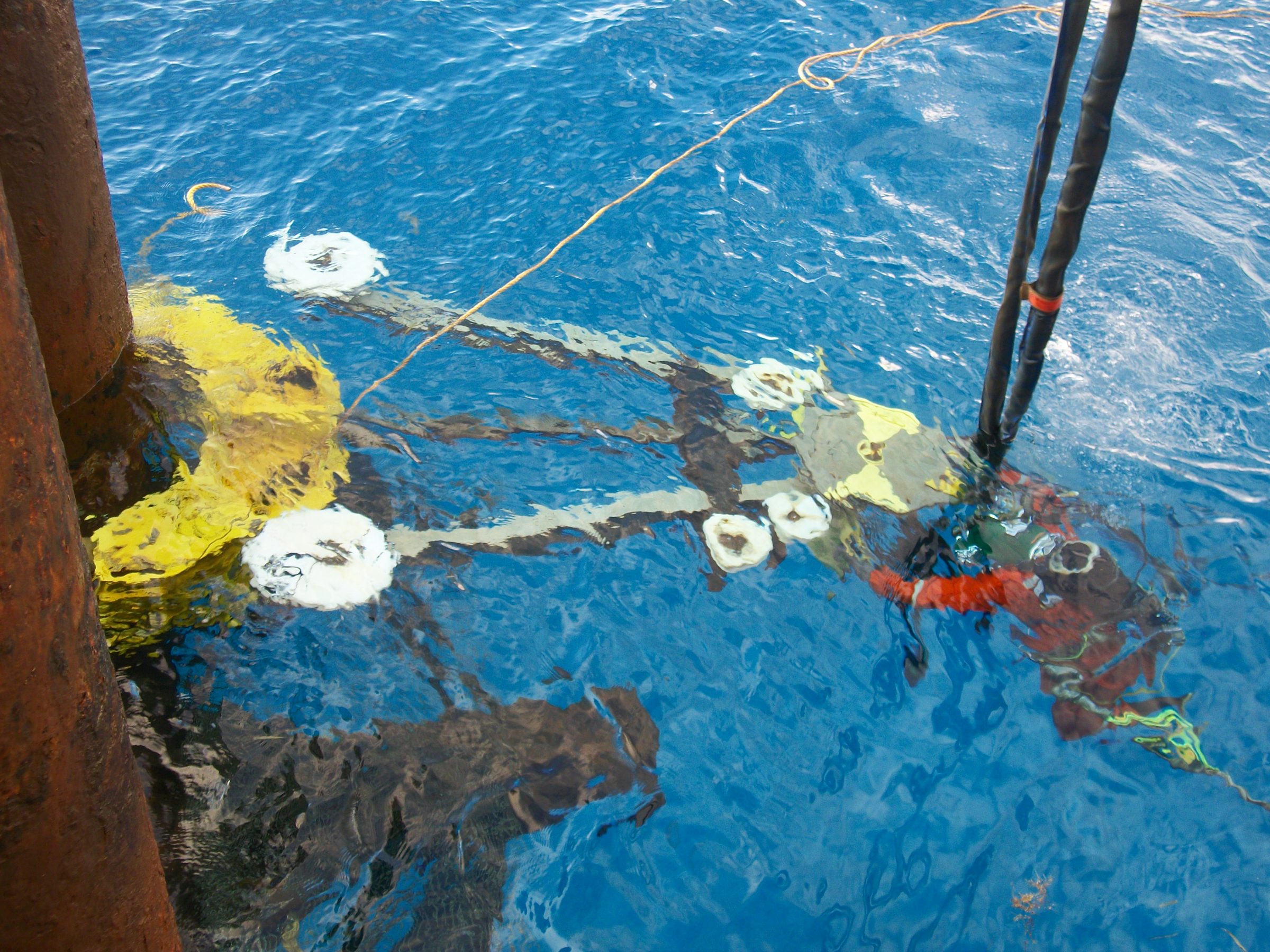

The work began with operators core drilling 57 holes measuring 8 centimeters (3.1 inches) in diameter and 55 holes 12 centimeters (4.7 inches) in diameter to an average depth of 2 meters (6.6 feet) through the concrete tunnel wall. Core drill rigs supplied by Diamond Products were used to make the holes, with the 8-centimeter (3.1-inch) and 12-centimeter (4.7-inch) diameter holes taking an average of three and four hours respectively using bits and tube extensions supplied by Husqvarna and DTT Canada. These holes were used for diamond wire runs and for attaching rigging and lifting equipment once the cut sections were ready for removal.

With all access holes completed, a length of diamond wire approximately 36 meters (118.1 feet) was threaded through two of them—spaced 6 meters (19.7 feet) apart across the width of the roof area—to set up the first loop for a pull cut. The cutting contractor essentially split the tunnel roof into 26 sliced sections. With the wire saw and operator positioned at one side of the cut area and the wire looped through the opposite side, sawing began. The operator made regular adjustments to the speed, tension and water supply as the wire made the 6-meter (19.7-foot) cut across the width of the tunnel to the core hole on the other side.

Cutting thickness began at 3 meters (9.8 feet), decreased to 2 meters (6.6 feet) and back again as the wire moved across the tunnel roof from one side to the other. Each cut took around six hours to complete. Capital Cutting & Coring operators made 14 cuts like this, then an additional three cuts measuring 5 meters (16.4 feet) long where the cutting area narrowed.

Each cut section weighed between 25 and 30 tons (65,000 pounds).

With all these cuts complete, the wire saws were set up to make a series of cuts to free the 26 sliced sections. In total, 29 pull cuts were made in widths from 1 to 3 meters (3.3 to 9.8 feet) and each section was rigged and secured by crane. Wire sawing would stop once the section was completely free from the tunnel wall and the crane could lift it out to street level.

The wire sawing work done by Capital Cutting & Coring produced 26 pieces each weighing between 25 and 30 tons. Each one was lifted out by crane before being removed from the jobsite and crushed at a local quarry. In total, the contractor performed 144 linear meters (472.4 feet) of cutting that led to over 700 tons (1,400,000 pounds) of concrete being removed from the Parliament Station site.

“Our biggest challenge was keeping all three wire saws running 24/7 until completion of the work,” said Thompson. “We arranged to have a suitable supply of backup equipment and spare tooling to minimize lost time in the event of any malfunctions or breakages. I’d also like to thank everyone from Canadian Cutting and Coring in Mississauga who assisted us with this job.”

However, before any wire sawing work was done engineers were brought to the jobsite to consult and assess the contractor’s plan. In particular, the engineers had to be sure that the weight of the cut pieces would be within the crane’s load capacity and that the street above the station could handle the weight of the crane while lifting the loads. Once the engineers were satisfied that the job was feasible and safe, the contractor moved forward.

While working around the tunnel roof opening, wire saw operators and other workers were tied off to avoid falls and the general contractor made sure pedestrians and street traffic did not encroach within the work area.

All wire sawing tasks at the OLRT Parliament underground station were completed on time and within budget. As a result of the cutting contractor’s success on this job, additional work has been awarded on the Confederation Line project.

“Capital Cutting & Coring has been an asset to our construction teams. Working within the busy capital of Canada and meeting very sensitive deadlines has its stresses, but the cutting contractor helped relieve some of this stress. The complexity of constructing an underground rail system has had many challenges, so working with professionals was the only way to insure a positive result,” explained William Coleman C.E.T. GSC an OLRT-c/RTG Construction Manager.

Completion of the 2.5-kilometer (1.6-mile) downtown tunnel has now been achieved and, after an extended period of testing, Phase 1 of Ottawa’s light rail transit system, the Confederation Line, will begin full revenue service in 2018.

The Confederation Line

Ottawa’s population is projected to grow 30 percent by 2031 and the city’s public transportation is already near or at capacity in the downtown core. Therefore, in November of 2008, Ottawa City Council approved a Transportation Master Plan laying the foundation for Ottawa’s light rail transit (LRT) project and the contract for the Confederation Line was awarded in February 2013.

The line runs 12.5 kilometers (7.8 miles) from Tunney’s Pasture Station in the west to Blair Road in the east and includes 13 stations. Much of the route runs within the city’s existing Transitway, with the terminus stations integrating into the Bus Rapid Transit system at Blair Station, Hurdman Station and Tunney’s Pasture Station. At Bayview Station, the Confederation Line links up with the north-south running O-Train.

However, the $2.1-billion CAD ($1.6-billion USD) Confederation Line is designed to be more than a solution to Ottawa’s long-term transit needs—it will also generate significant economic, environmental, cultural and social benefits for the city and its residents. It will launch with a planned peak capacity of 10,700 passengers per hour in each direction, with potential to grow to over 18,000 passengers per hour in each direction by 2031. With a tunnel through the downtown core, travel time from one end to the other will be less than 24 minutes—any time of day. By using zero-emission electric trains and encouraging commuters to leave their cars at home, it is hoped that the line will provide a reduction in both air and noise pollution. The investment in this new system has generated thousands of direct and indirect jobs, and will provide a total economic output of approximately $3.2 billion CAD ($2.5 billion USD).

Company Profile

Capital Cutting & Coring Ltd. has been a CSDA member since 1989 and is based in Ottawa, Ontario, Canada. The company has been in business for over 30 years, has 50 employees, 16 trucks and offers the services of core drilling, wall sawing, wire sawing, flat sawing, selective demolition and ground penetrating radar imaging.

Resources

General Contractor:

Rideau Transit Group, Ottawa Light Rail Transit Constructors

Sawing and Drilling Contractor:

Capital Cutting & Coring Ltd.

Ottawa, Ontario, Canada

Phone: 613-737-5227

Email: dave@capcut.com

Website: www.capcut.com

Methods Used: Wire Sawing, Core Drilling