Preferred Parking

Aging Parking Structure Refurbished Using Diamond Tools

A deteriorated 564-space, five-story parking garage in the busy center of downtown Columbus, Ohio, has been given a new lease on life with help from a professional concrete cutting contractor.

The 564-space , five-story parking garage had fallen into disrepair.

To allow the structure to be safe and fully-functional once more, the contractor performed over 750 feet of horizontal and inverted wall sawing on the garage’s 10-inch-thick concrete deck slabs and created 64 beam pockets to allow the installation of new steel reinforcing I-beams. In addition, a number of openings were made using core drills for the installation of plumbing lines and utility ducts.

The parking garage, located at 56-62 Long Street, was closed in September 2013 by the City of Columbus due to structural problems. Built in 1954, it had been reported that concrete from the garage was breaking off from overhead beams and bowed deck slabs and falling on cars parked below. Previous plans to refurbish and reopen the garage had failed, and it had remained out of service since its closure. Then, in early 2016, the garage was acquired by Connect Realty with a view to it becoming part of a larger redevelopment scheme.

The new owners had already acquired two buildings nearby and plans were underway to convert the spaces into “microliving” apartments—a mix of one-bedroom, studio and small apartments ranging in size from 300 to 870 square feet of living space—along with street-level offices and storefronts. Realizing that parking options were limited around the properties, the developers moved to purchase the parking garage. The plans for the structure included the installation of glass windows on two sides, the addition of heating systems for the upper levels, the conversion of the ground floor to management offices and the addition of an on-site car wash and valet service. Before these plans could become a reality, however, the garage had to be structurally sound.

General contractor Mid Ohio Contracting Services, Ltd. of Columbus needed to find a specialty concrete sawing and drilling company that could create the required beam pockets and deck slab cuts on the waning structure with high precision and low vibration. The job was awarded to CSDA member Donley Concrete Cutting Co. of Pickerington, Ohio.

“This job was not going to be without its challenges,” said Donley Concrete Cutting operations manager Jason Young. “The specifications we were given had tight tolerances. The steel framework was prepared and fabricated off-site and needed a precise layout so that each component would connect together. Methods like jackhammering had been ruled out prior to us winning the job due to a lack of accuracy and excessive vibration, but even hand sawing the pockets was not going to be accurate enough. Therefore, we chose track-mounted wall sawing techniques. This gave us the precision and sawing speed, but the setup and takedown for each cut was going to take time we didn’t have.”

A custom mount was fabricated to secure the wall saw to the concrete structure.

The cutting contractor had been given four weeks to complete all sawing and drilling tasks, so the focus turned to streamlining the setup and takedown process of the wall saw. Donley Concrete Cutting fabricated a rigid floor mount for the saw and customized a gear rack setup to move it from one cut location to the next. This allowed the operator to perform multiple cuts from each mounted setup. The saw was anchored to the slab and leveled before cutting began. For both the horizontal and inverted cuts on the garage’s deck slabs, the notches created had to be level so that the steel beams sat correctly. Most of the parking deck slabs were bowed in one direction, so the contractor had to make slight adjustments as necessary.

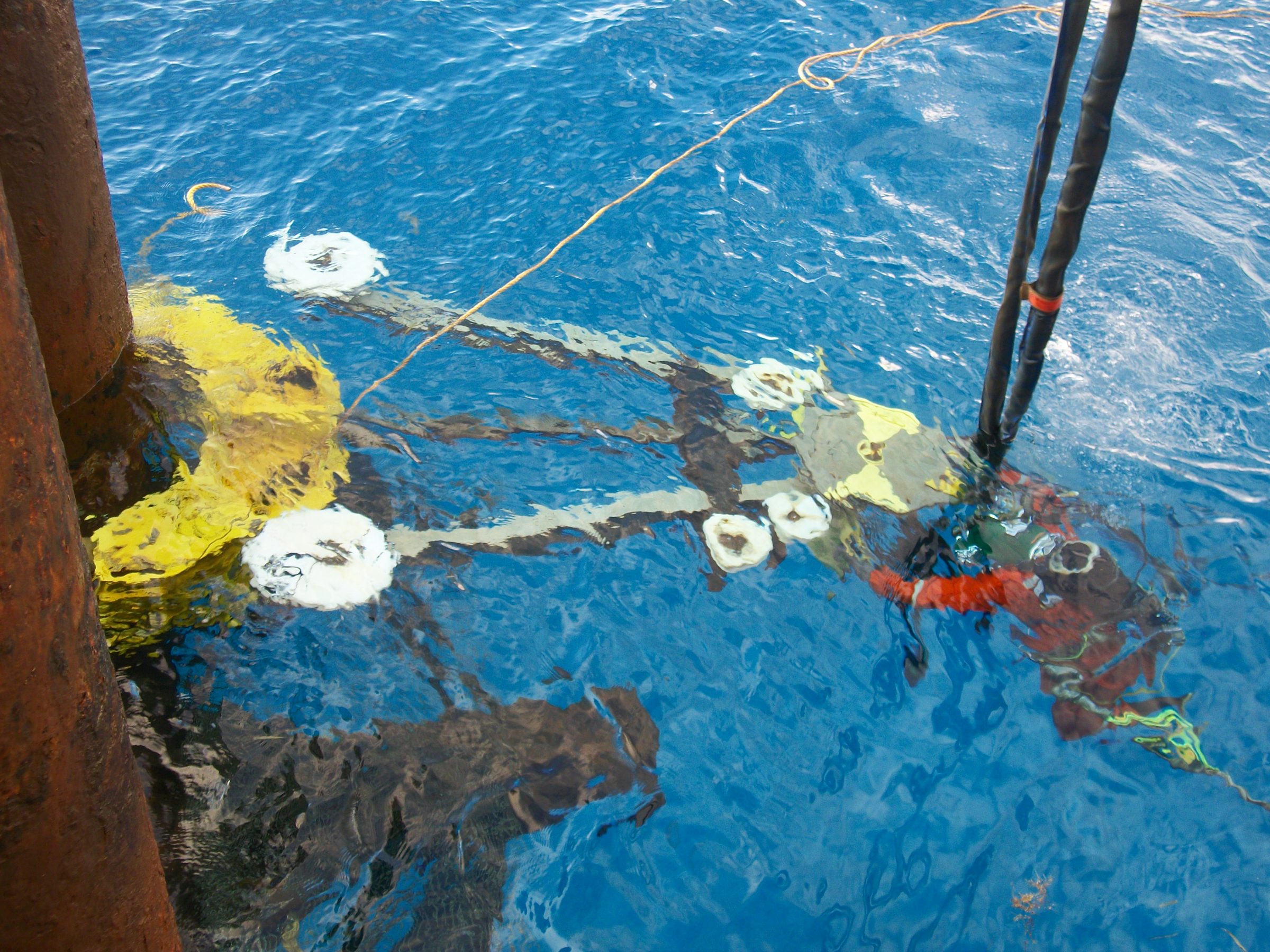

For the 2-inch-wide, 5-inch-deep beam pockets, the wall saw operator performed each cut from inside a man lift while an assistant would stay on the slab to hand crank the saw to each of the 64 cut locations. Both employees were tied off and wore the appropriate PPE for the job.

A Pentruder 8-20 high frequency wall saw fitted with a 32-inch-diameter blade supplied by Diamond Tools Technology was employed to complete the cutting work. Mounted to the contractor’s custom-fabricated gear rack, the operator and assistant made four individual cuts off one setup with the saw. After each pocket was created, the pair would reset the saw at the next location and repeat the procedure for all 64 pockets. This took approximately two weeks. Thanks to the ingenuity of the cutting contractor, only 64 track-mounted setups were required to complete the pockets instead of 256—one for each individual cut.

Next, Donley Concrete Cutting made a series of horizontal and inverted wall saw cuts on each deck slab face, which were performed using traditional mounting and sawing techniques. The inverted cuts were done with the operator a safe distance away in the man lift, operating the saw by remote control. Each 100-foot section of cutting took one day to complete. The diamond cutting work left a smooth, clean finish for the general contractor to install its steel channels.

“Many of the specified cut locations had us sawing through existing steel reinforcing rebar in the parking garage slabs and these locations could not be moved. However, this proved to be little problem for the saw’s rigid mount setup and the power we got from the Pentruder system,” explained Young.

With all sawing work completed for the rehabilitation and strengthening of the deck slabs, the cutting contractor turned its attention to the sawing and drilling of duct and utility openings. Operators created eight 36-inch square and four 25-inch square duct openings in one week using the Pentruder wall saw and an ICS chain saw to eliminate overcuts. In addition, 50 core holes measuring 9 inches in diameter were made for floor drains. The contractor employed a Hilti DD 350 core drill for these openings, which were completed floor-by-floor as needed by the plumbing contractor on site.

A series of 64 beam pockets were required to house new reinforcing steel framework.

Over the course of two months, Donley Concrete Cutting complete 387 feet of horizontal wall sawing in the face of each parking deck slab followed by 387 feet of inverted wall sawing on the bottom. These cuts successfully created space for steel channels to be fitted. Also, the contractor made 64 beam pockets that consisted of two 2-inch-wide by 5-inch-deep openings in the 10-inch-thick concrete deck slab. The use of diamond tools and equipment, coupled with the custom-fabricated mount, enabled the cutting team to complete all specified tasks ahead of schedule and within budget. Young gave his final thoughts on the job. “I was ecstatic with the outcome of this job. It required us to come up with innovative practices to complete the necessary cuts in a safe and streamlined process,” he stated.

The CSDA member’s work was completed between January and March 2017 and the refurbished parking garage on Long Street should reopen later in the year, providing much-needed parking for residents and workers of downtown Columbus.

Zack Forster, supervisor with Mid Ohio Contracting Services, said, “Donley Concrete Cutting did an exceptional job! The team performed well and did everything they were asked to do, finishing ahead of schedule. The guys were very easy to work with, which made this portion of the job go very smooth.”

Company Profile

Donley Concrete Cutting Co. has been a CSDA member since 2004 and is based in Pickerington, Ohio, with a support location in Cincinnati. The company has been in business for 20 years. It has 60 employees, 50 trucks and offers the services of core drilling, wall sawing, wire sawing, flat sawing, curb sawing, diamond grooving and grinding, profilograph services, selective demolition and ground penetrating radar.

Resources

General Contractor:

Mid Ohio Contracting Services, Ltd.

Sawing and Drilling Contractor:

Donley Concrete Cutting Co.

Pickerington, Ohio

Phone: 614-834-0300

Email: Jason.young@donleyconcrete.com

Website: www.donleyconcrete.com

Methods Used: Wall Sawing