Tiny but Mighty: Smaller Machines Can Be Perfect for the Job

In South Florida, a private residence was planning a renovation project to update their single-story house into a more modern and spacious two-story house. The project required the slab-on grade foundation to be cut out in areas to install new footings and excavate the area to pour concrete to support the new architecture. They also needed to cut out concrete beams and walls to raise the elevation of the house according to the project specifications and plans.

Enter CSDA member Right Way Drilling and Scanning of South Florida. Originally, the general contractor wanted to bring in heavy machinery to quickly carry out demolition, and certainly, larger machinery would have expedited the demolition process itself. However, and justifiably, the customer wanted to prevent any damage to the surrounding landscaping. Right Way operators Richard Semidey, Ivan Herrera and Eric Figueroa chose to employ a mini skid steer and saw cutting equipment to accommodate the customer’s request.

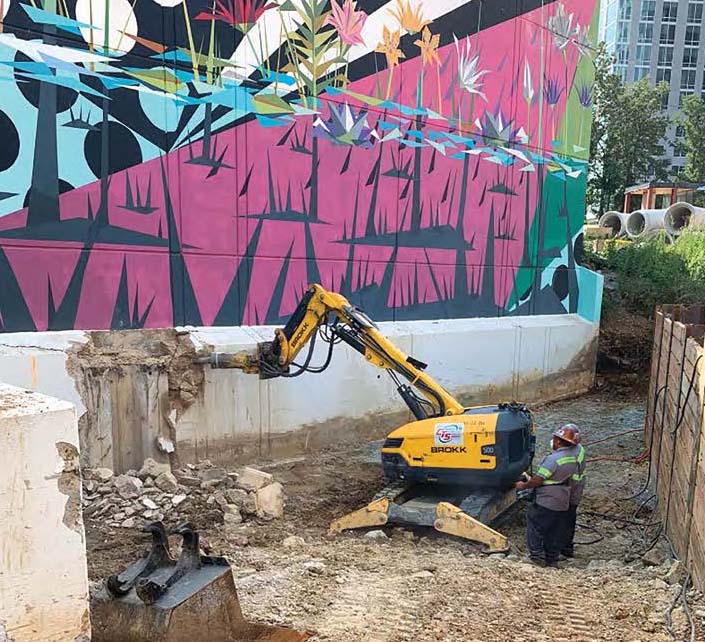

The Right Way team arrived well-prepared for the project and took the time to properly plan and coordinate the work with the customer. This was important in ensuring a successful project, as it helped to avoid any misunderstandings or delays later on. After a walk-through with the customer, Right Way operators set up to first cut the walls and beams with the 24” hand saw and Bobcat MT100 mini track loader with a breaker attachment, and the floor was left for last.

Setting up to cut walls and beams with a handsaw and mini skid steer was a calculated choice by Right Way, as it allowed for precise and controlled cutting while minimizing the potential for damage to surrounding structures, especially in a tight space such as this. Leaving the floor for last was also a good strategy, as it allowed for easier cleanup and removal of debris. At the end of the day, operators made sure the workspace was clean and debris was collected. Right Way operators emphasized that keeping the job site clean and organized was important not only for safety, but also for maintaining a professional appearance and ensuring that work could continue smoothly in the days ahead for the other contractors.

During the removal, the team occasionally used a CB35 Diamond Products hydraulic power unit which was necessary to sawcut in the more cramped areas. Operators solved this concern by using the MT100 with a fork attachment to support the beam while sawing. This was to prevent any injuries to the saw cutter if the beam were to accidentally fall. The team took a careful and methodical approach to the project, which contributed to its success.

Overall, thirty-one cuts from slab through header, approximately 10’ above finished floor on concrete masonry unit walls of which headers total approximately 120’ long. A total of twenty 310’ long exterior openings were created. 140’ of 4”–6” concrete slab which is cutting and popping, some areas up to 14” thick. The team handled disposal of all the concrete debris by loading it onto a dump trailer with a bobcat.

The job was completed on time and on budget. The customer has also used Right Way on several other projects after. Semidey, President of Right Way Drilling and Scanning, said about the project, “We were very pleased with outcome of the project. Everything went to plan, and the customer was happy with the end result. We have built a good relationship with this customer because they know we are reliable and team players. It’s always important to listen to and work closely with the customer to find solutions that meet their needs and expectations while still ensuring the success of the project.” Being safe and professional is crucial for any contractor, and it’s especially important for concrete cutting and drilling contractors, who work with heavy machinery and potentially hazardous materials. CSDA contractors are held to high standards of safety and professionalism, and they often offer a wide range of services to meet the needs of their customers.

By providing a broad range of services, CSDA contractors can help their customers save time and money by having a single contractor handle multiple aspects of a project. This can also help to build trust and establish long-term relationships with customers, who will be more likely to return for future projects and recommend the contractor to others. Ultimately, a focus on safety, efficiency, and broad service offerings is what helps CSDA contractors build a strong reputation in the industry and maintain a successful business over the long term.

COMPANY PROFILE Right Way Drilling and Scanning LLC is located in Tamarac, Florida, and has been operating since early 2019. They currently have three trucks and four employees, and offer concrete sawing, core drilling, selective demolition, GPR scanning and utility locating. They have been a CSDA member since 2019. RESOURCES General Contractor: Riteway Demolition CSDA Contractor: Right Way Drilling and Scanning LLC Contact: Richard Semidey Email: richard@rightwaycutting.com Tel: 954-383-8611 Website: www.rightwaycutting.com Methods Used Selective Demolition, Hand Sawing